PET umgca Granulating

Infrared Crystallization Dryer for rPET Extrusion umgca granulating

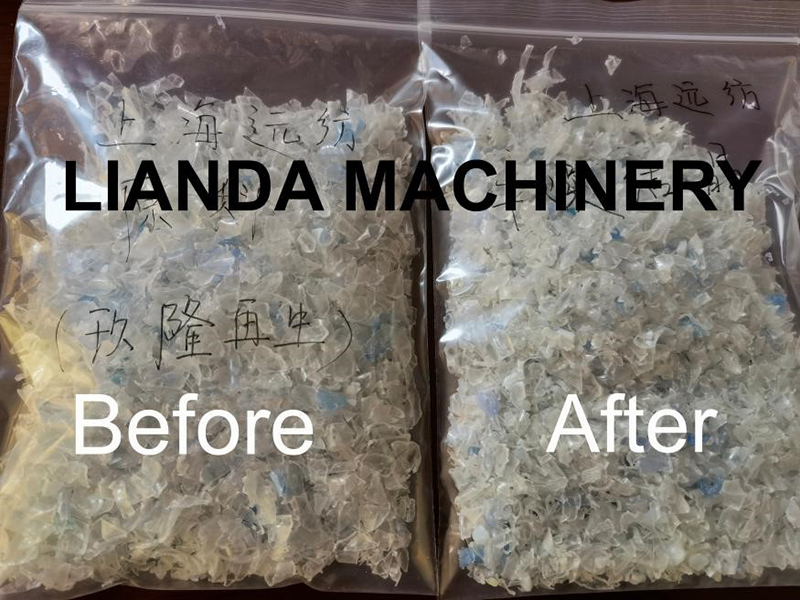

I-infrared Pre-Drying ye-rPET Bottle Flakes: Ukunyusa imveliso kunye nokuphucula uMgangatho kwi-PET Extruders

Ukomisa lolona tshintsho lubalulekileyo ekuqhubeni.

>> Ukuphucula ukwenziwa kunye neepropathi zendalo ezisetyenzisiweyo, i-PET yebakala lokutya ngetekhnoloji eqhutywa sisibane se-infrared inendima ebalulekileyo yokudlala kwipropathi ye-intrinsic viscosity (IV)

>> I-crystallization yangaphambili kunye nokomiswa kweeflakes ngaphambi kokukhutshwa kunceda ukunciphisa ilahleko ye-IV evela kwi-PET, eyona nto ibalulekileyo ekusetyenzisweni kwakhona kwe-resin.

>> Ukuhlaziya iiflakes kwi-extruder kunciphisa i-IV ngenxa ye-hydrolysis i ubukho bamanzi, kwaye yiloo nto ukomisa kwangaphambili ukuya kwinqanaba lokumisa elilinganayo kunye neNkqubo yethu ye-IRD kunokunciphisa oku kuncipha.Ukongeza,i-PET melt strips ayijiki ibe tyheli kuba ixesha lokumisa liyancipha(Ixesha lokumisa lifuna kuphela i-15-20mins, umswakama wokugqibela unokuba ≤ 30ppm, ukusetyenziswa kwamandla ngaphantsi kwe-80W / KG / H)

>> Ukucheba kwi-extruder kukwancitshiswa ngenxa yokuba izinto ezifudunyeziweyo zingena kwi-extruder kwiqondo lobushushu elingaguqukiyo"

>> Ukuphucula imveliso yePET Extruder

Ukunyuka kobuninzi be-bulk density nge-10 ukuya kwi-20 % kunokufezekiswa kwi-IRD, kuphucula ukusebenza kwesondlo kwindawo yokungena e-extruder kakhulu - ngelixa isantya se-extruder sihlala singatshintshi, kukho ukuphuculwa kakhulu kokuzaliswa kokusebenza kwi-screw.

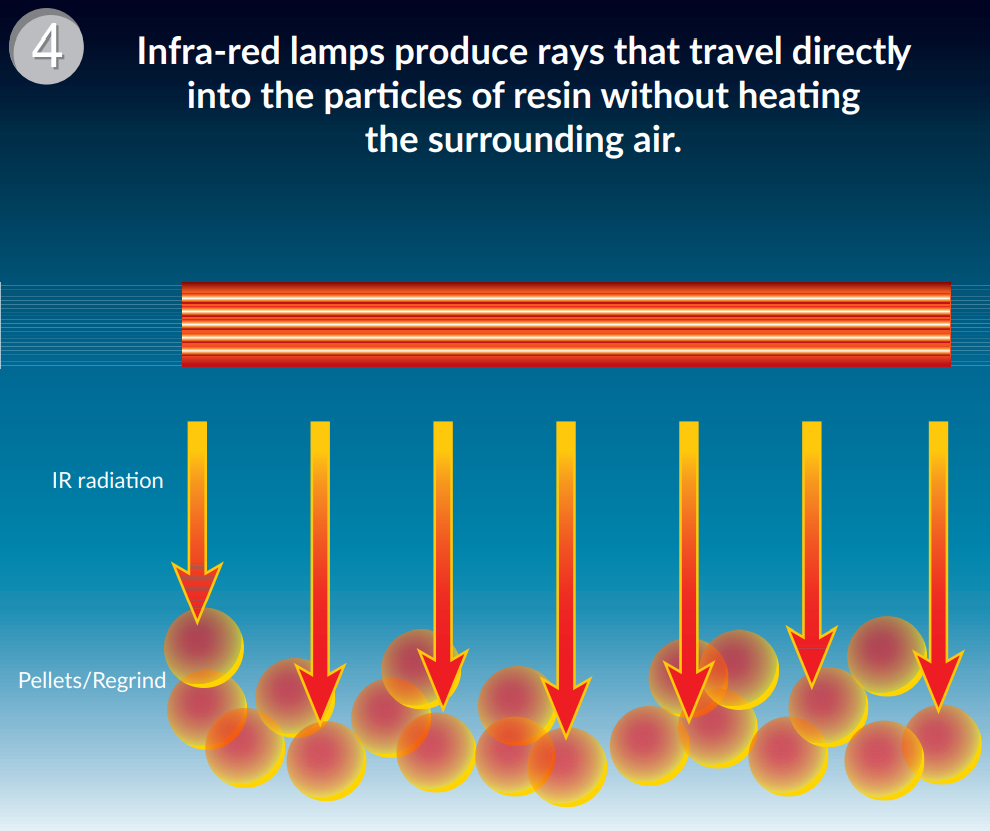

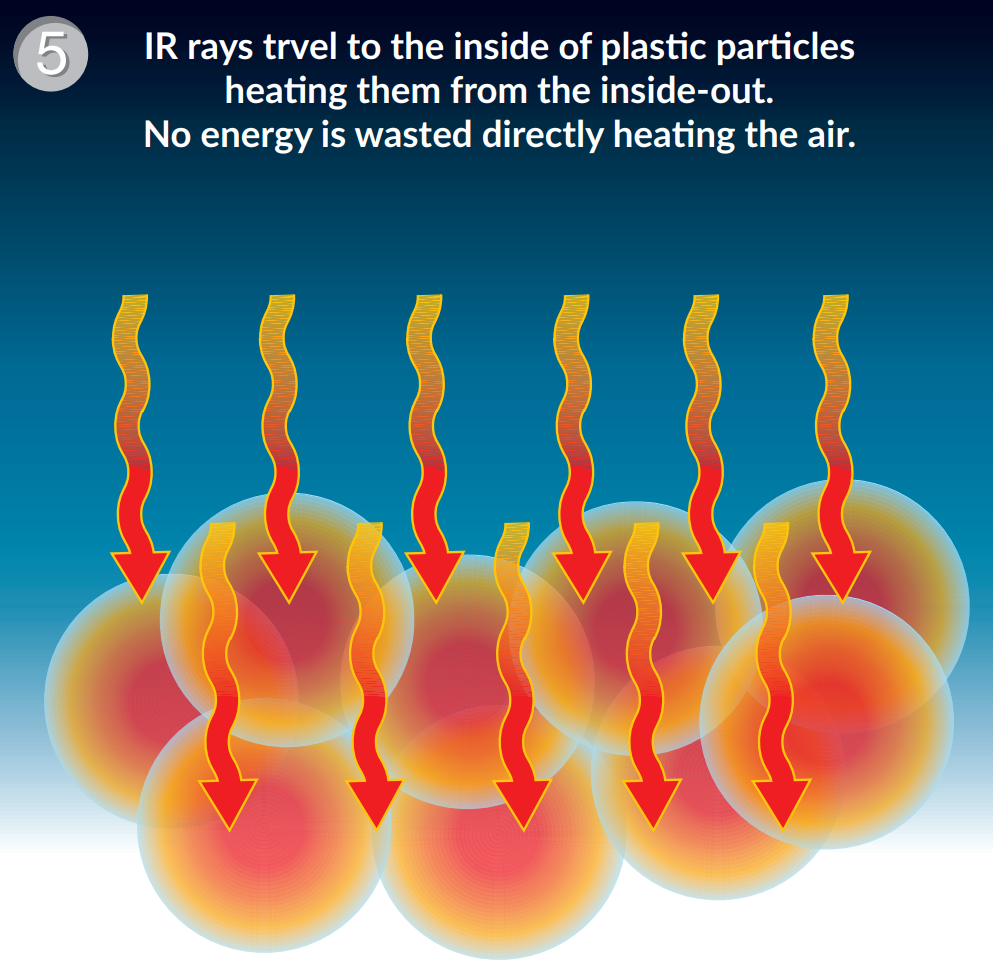

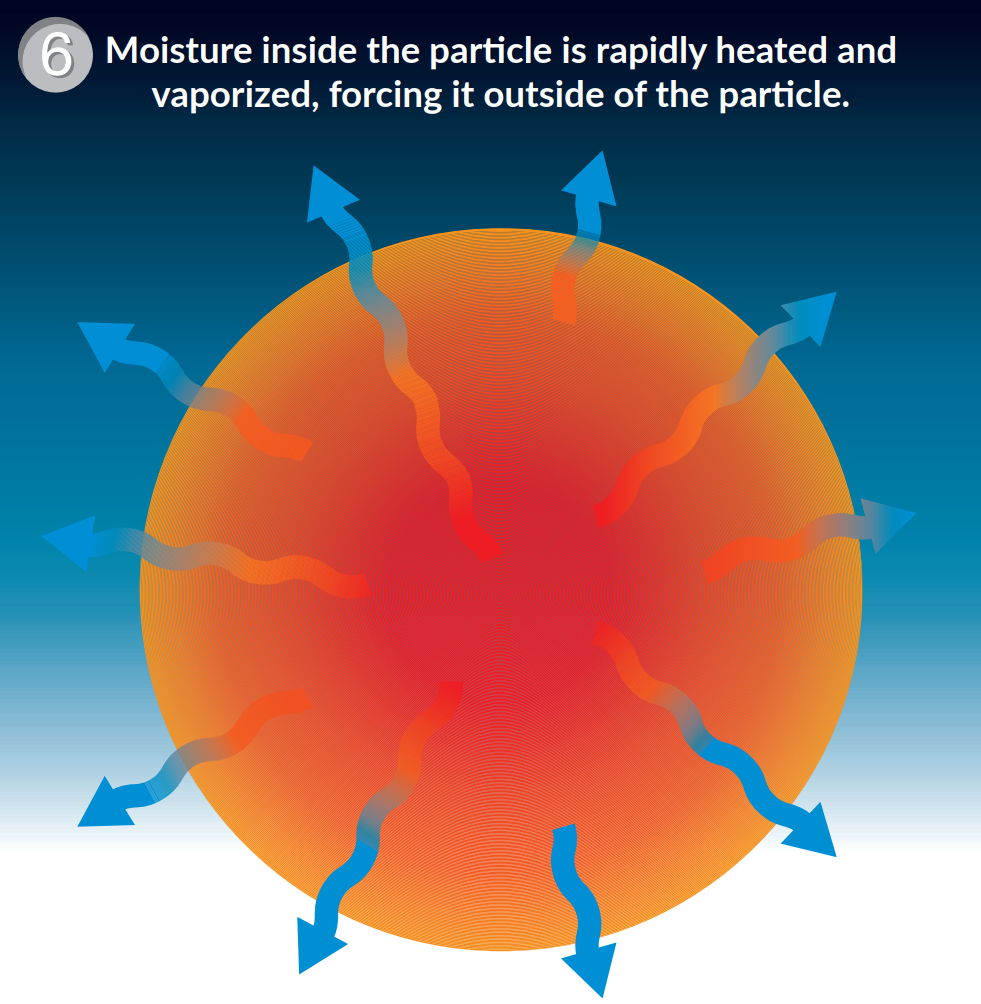

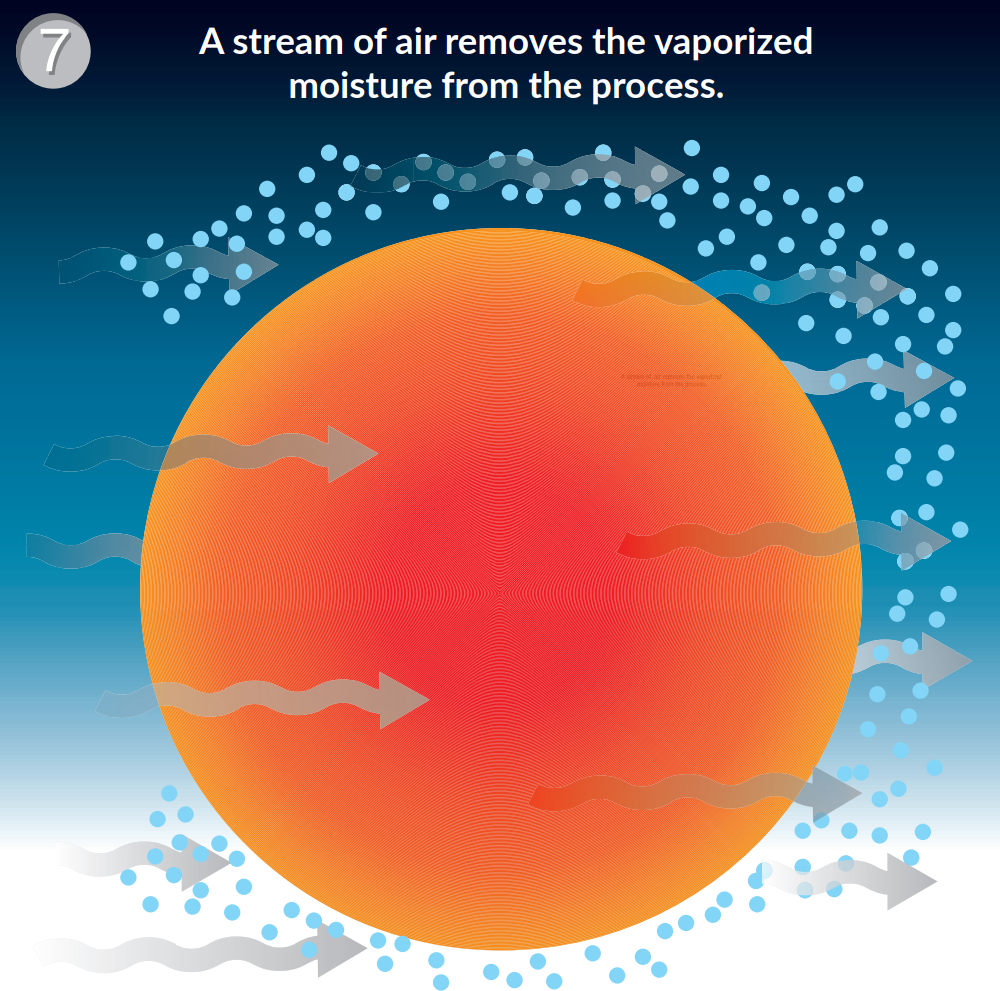

Umgaqo wokuSebenza

I-Advantage Siyenzayo

※Ukunciphisa ukuthotywa kwe-hydrolytic ye-viscosity.

※ Thintela ukunyuka kwamanqanaba e-AA kwizinto ezinoqhagamshelwano lokutya

※ Ukwandisa umthamo wemveliso ukuya kwi-50%

※ Uphuculo kwaye wenze umgangatho wemveliso uzinze-- Ukulingana kunye nokuphindaphinda umxholo wokufuma wesixhobo

→ Nciphisa iindleko zokwenziwa kweepellets zePET: Ukuya kutsho kuma-60% ngaphantsi kokusetyenziswa kwamandla kunenkqubo eqhelekileyo yokomisa

→ Ukuqalisa kwangoko kunye nokuvala ngokukhawuleza --- Akukho mfuneko yokufudumeza kwangaphambili

→ Ukomisa nokuqaqambisa kuya kuqhutywa kwinyathelo elinye

→ Umgca womatshini uxhotyiswe nge-Siemens PLC inkqubo kunye nomsebenzi omnye wememori engundoqo

→ Igubungela indawo enesakhiwo esincinci, esilula kwaye kulula ukuyisebenzisa kunye nokugcinwa kwayo

→ Ubushushu obuzimeleyo kunye nexesha lokumisa elibekiweyo

→ Akukho lucalu-calulo lweemveliso ezinobunzima obahlukeneyo

→ Ukucoca ngokulula kwaye utshintshe imathiriyeli

Ukuqhuba koomatshini kumzi-mveliso wabathengi

FAQ

Umbuzo: Ngowuphi ukufuma kokugqibela onokukufumana?Ingaba unayo nayiphi na imida ekunyakameni kokuqala kwemathiriyeli ekrwada?

A: Umswakama wokugqibela esinokuwufumana ≤30ppm (Thatha i-PET njengomzekelo).Ubumanzi bokuqala bunokuba yi-6000-15000ppm.

Q: Sisebenzisa i-Double parallel screw extruding kunye ne-vacuum degassing system ye-PET Extrusion umgca wegranulating, ngaba kuya kufuneka sisebenzise i-pre-dryer?

A: Sicebisa ukuba usebenzise i-pre-dryer ngaphambi kokukhutshwa.Ngokuqhelekileyo inkqubo enjalo ineemfuno ezingqongqo kumswakama wokuqala we-PET.Njengoko sisazi ukuba i-PET luhlobo lwemathiriyeli enokufunxa ukufuma kwi-atmosfera eya kubangela ukuba umgca we-extrusion usebenze kakubi.Ke sicebisa ukuba usebenzise isomisi sangaphambili phambi kwenkqubo yakho ye-extrusion:

>> Ukunciphisa ukuthotywa kwe-hydrolytic ye-viscosity

>>Thintela ukunyuka kwamanqanaba e-AA kwizinto ezinoqhagamshelwano lokutya

>> Ukwandisa umthamo wemveliso ukuya kuthi ga kwi-50%

>> Uphuculo kwaye wenze umgangatho wemveliso uzinze-- Ukulingana kunye nokuphinda-phinda isiqulatho sokufuma kwesixhobo

Umbuzo: Liliphi ixesha lokuhanjiswa kwe-IRD yakho?

A: Iintsuku zokusebenza ezingama-40 ukusukela oko sifumene idiphozithi yakho kwiakhawunti yenkampani yethu.

Umbuzo: Kuthekani ngofakelo lwe-IRD yakho?

Injineli enamava inokunceda ukufakela inkqubo ye-IRD kumzi-mveliso wakho.Okanye sinokubonelela ngenkonzo yesikhokelo kwi-line.Umatshini wonke wamkela iplagi yokubhabha, kulula ukuyidibanisa.

Umbuzo: Yeyiphi i-IRD enokwenzelwa yona?

A: Inokuba pre-dryer for

- PET/PLA/TPE Sheet extrusion line line

- I-PET Bale intambo yokwenza umgca womatshini

- I-PET masterbatch crystallization kunye nokomisa

- PETG Sheet umgca extrusion

- Umatshini we-PET monofilament, i-PET monofilament extrusion line, i-PET monofilament yomtshayelo

- I-PLA / PET Umatshini wokwenza ifilimu

- PBT, ABS / PC, HDPE, LCP, PC, PP, PVB, WPC, TPE, TPU, PET (Bottleflakes, granules, flakes), PET masterbatch, CO-PET, PBT, PEEK, PLA,PBAT, PPS njl.

- Iinkqubo zokushisa zeukususwa kwe-oligomeren yokuphumla kunye namacandelo aguquguqukayo.