Iipaliti ze-rPET I-Crystallization Dryer

I-PET Infrared crystallization Dryer ye-R-PET Pellets -----ID yeTekhnoloji ye-OD Yenziwe

>> Yomisa & uCrystallize PET Chips/Flake/Pellets in 20mins at 30ppm ngokonga i-45-50% yeendleko zamandla.

- Ukuya kuthi ga kwi-60% ngaphantsi kokusetyenziswa kwamandla kunenkqubo eqhelekileyo yokomisa

- crystallization efanayo

- Akukho iipellet ezidibanisayo kunye nokuncamathela

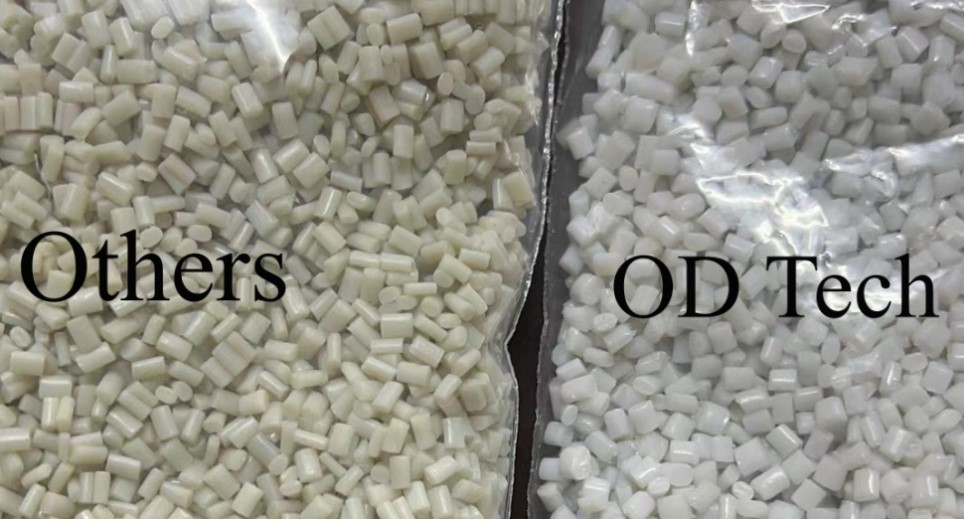

- Umbala weCrystallization Ubisi olumhlophe

- Ngononophelo unyango lwezinto

- Ukuqalisa kwangoko kunye nokuvala ngokukhawuleza

- Ukushisa okuzimeleyo kunye nexesha lokumisa libekwe

- Akukho ulwahlulo lweemveliso ezinobunzima obuhlukeneyo

- Ukucoca ngokulula kunye nokutshintsha izinto

Ulinyusa njani ixabiso elongeziweyo lemveliso ye-R-PET Pellets/ PET Pellets ezenziwe yiBottle flakeInfrared crystallization Dryer?

| 1 | I-crystallization efanayo, iphezulu kwinqanaba le-crystallization Umbala weCrystallization: mhlophe qwa

|

Ixabiso lokuthengisa liya kuba yi-USD30-50 ngetoni nganye

|

| 2 | I-Crystallization kunye neyomileyo iya kugqitywa kwinqanaba elinye Ukufuma kokugqibela kunokuba ≤50ppm | Kuya kuba yinto efanelekileyo kumsebenzisi olandelayo, njengokwenziwa kwe-PET Preform, ukuveliswa kwe-PET Sheet okanye ukuveliswa kweFiber njl. Kuya kunciphisa ixesha labo lokumisa kwangaphambili. |

| 3 | Gqibezela umatshini olawulwa yi-Siemens PLC Isikrini sokuchukumisa kunye nomsebenzi wememori, isiqalo esisodwa esibalulekileyo. | Ukunciphisa iindleko zomsebenzi wobuchule. |

| 4 | Yonga phantse i-45-50% yeendleko zamandla xa kuthelekiswa ne-Dessicant dryer | Thatha i-500kg / h imodeli ye-infrared crystal dryer njengomzekelo, ixabiso lombane lingaphantsi kwe-100W / KG / HR |

Yintoni esinokukwenzela yona

>> Nciphisa ukuthotywa kwe-hydrolysis ye-viscosity.

>> Thintela ukwanda kwamanqanaba e-AA kwizinto ezinoqhagamshelwano lokutya

>> Ukwandisa umthamo wemveliso ukuya kuthi ga kwi-50%

>> Uphuculo kwaye wenze umgangatho wemveliso uzinze-- Ukulingana kunye nesiqulatho sokufuma esiphindaphindwayo

>> Kukho iindawo ezintathu zokulawula ubushushu be-PID, kwaye ubushushu bekristale bomisa bunokusetwa ngokweempawu zemathiriyeli ekrwada.

>> Isimbo sokusebenza esijikelezayo sinokusebenza njengomxube.Unokondla ipesenti ye-PET Chips kunye neepellets ezisetyenzisiweyo kwi-Infrared crystal dryer ngokuthe ngqo, iya kuxuba imathiriyeli ngokuzenzekelayo.

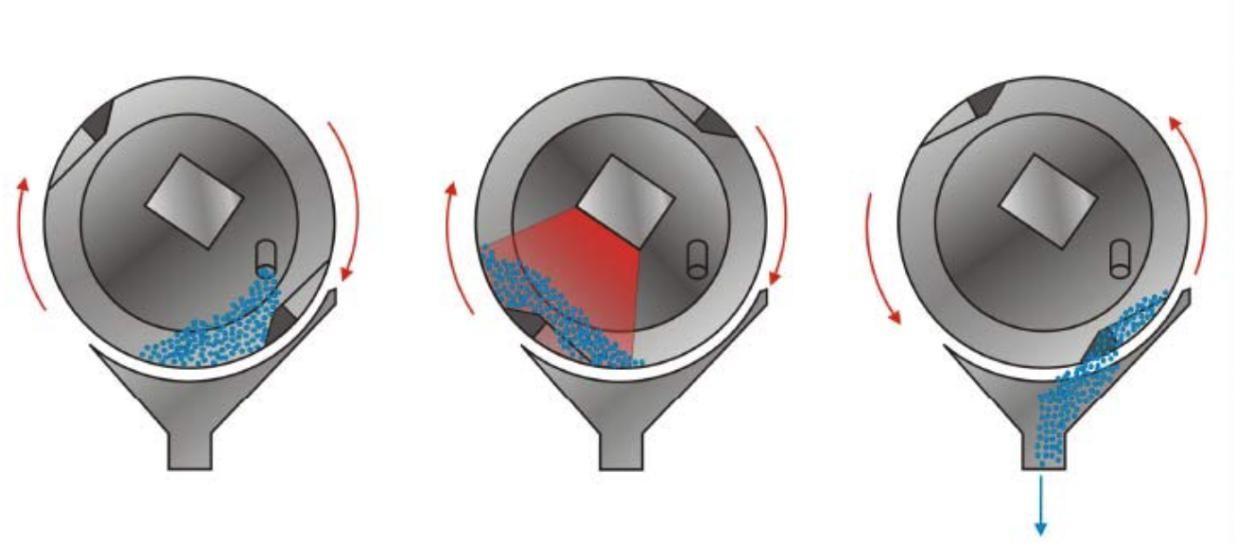

Indlela yokusebenza

Ukutya/Ukulayisha

Ukomisa & Crystallization Processing

Ukukhupha

>> Kwinqanaba lokuqala, ekujoliswe kuko kuphela kukufudumeza imathiriyeli ukuya kubushushu obusetwe kwangaphambili.

Yamkela isantya esicothayo somgqomo ojikelezayo, izibane ze-infrared zesomisi ziya kuba kwinqanaba eliphezulu, emva koko iipellets ze-PET zifudumeze ngokukhawuleza de ubushushu bunyuke ukuya kubushushu obusetwe ngaphambili.

>> Ukomisa kunye nenyathelo lokuqaqambisa

Emva kokuba izinto zifike kwiqondo lokushisa, isantya somgqomo siya kwandiswa ukuya kwisantya esiphezulu esijikelezayo ukuphepha ukudibanisa kwezinto.Ngexesha elifanayo, izibane ze-infrared ziya kwandiswa kwakhona ukugqiba ukomisa.Emva koko isantya sokujikeleza igubu siya kuthotywa kwakhona.Ngokuqhelekileyo inkqubo yokumisa iya kugqitywa emva kwe-15-20mins.(Ixesha elichanekileyo lixhomekeke kwipropati yezinto)

>> Emva kokugqiba inkqubo yokomisa, i-IR Drum iya kukhupha ngokuzenzekelayo izinto kwaye iphinde igcwalise idrum kumjikelo olandelayo.

Ukuzaliswa ngokuzenzekelayo kunye nazo zonke iiparitha ezifanelekileyo kwiirampu ezihlukeneyo zokushisa zihlanganiswe ngokupheleleyo kwi-state-of-art yolawulo lwe-Touch Screen.Nje ukuba iiparamitha kunye neeprofayili zobushushu zifunyenwe kwizinto ezithile, iisetingi zeethisisi zinokugcinwa njengeendlela zokupheka kwinkqubo yolawulo.

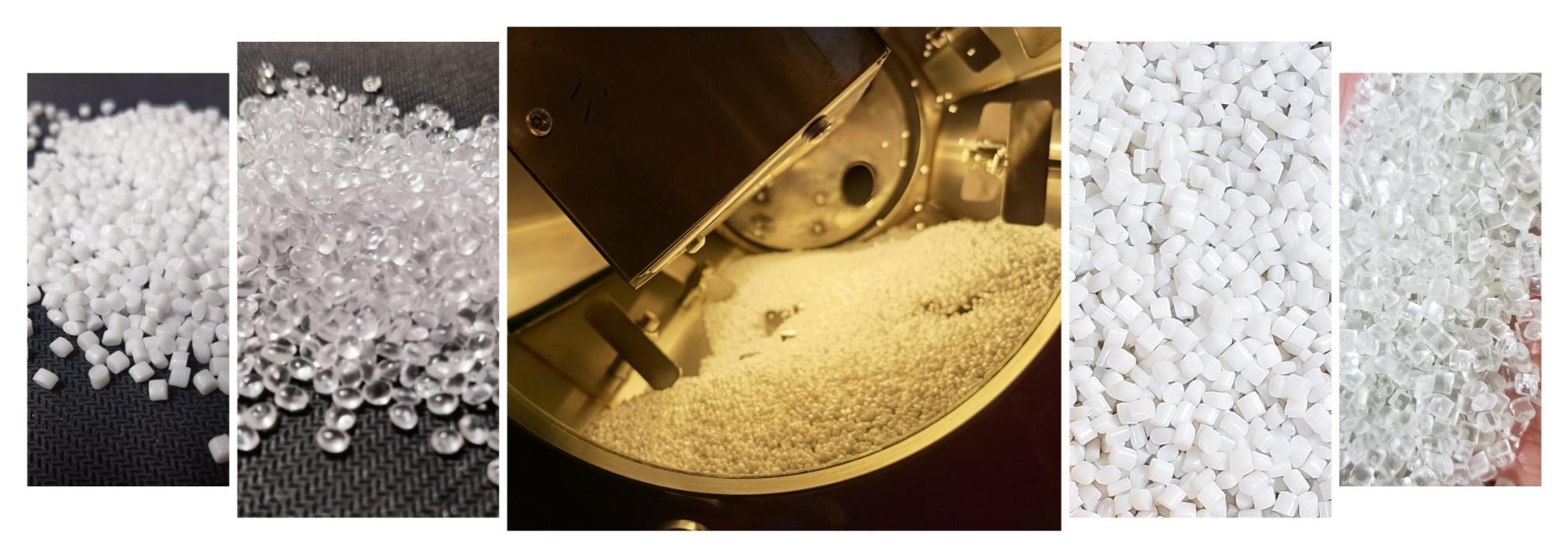

Iifoto zoomatshini zereferensi

Uvavanyo lwezinto eziphathekayo

Injineli enamava iya kwenza uvavanyo.Abasebenzi bakho bayamenywa ukuba bathathe inxaxheba kwiindlela zethu ezidibeneyo.Ngaloo ndlela unako zombini ukuba negalelo ngokusebenzayo kunye nethuba lokubona iimveliso zethu zisebenza.

>> Nikeza ngeNjineli enamava kumzi-mveliso wakho ukunceda ufakelo kunye novavanyo lwezinto eziphathekayo

>> Yamkela iplagi yendiza, akukho mfuneko yokudibanisa ucingo lombane ngelixa umthengi efumana umatshini kumzi-mveliso wakhe.Ukwenza lula inyathelo lofakelo

>> Nikeza ividiyo yokusebenza yofakelo kunye nesikhokelo esisebenzayo

>> Inkxaso kwinkonzo yomgca