Iplastiki yeDesiccant Desiccant Dehumidifier

Isampulu yosetyenziso

| Impahla engekasilwa | IiPellet zePET (Zenziwe ngeflake eRecycled) |  |

| Ukusebenzisa uMtshini | LDHW-600*1000 |  |

| Iseti yobushushu obukhazimlisiweyo | 200℃ | |

| Ixesha lekristali limisiwe | 20mins | |

| Izinto zokugqibela | IiPellet zePET eziQingqiweyo |  |

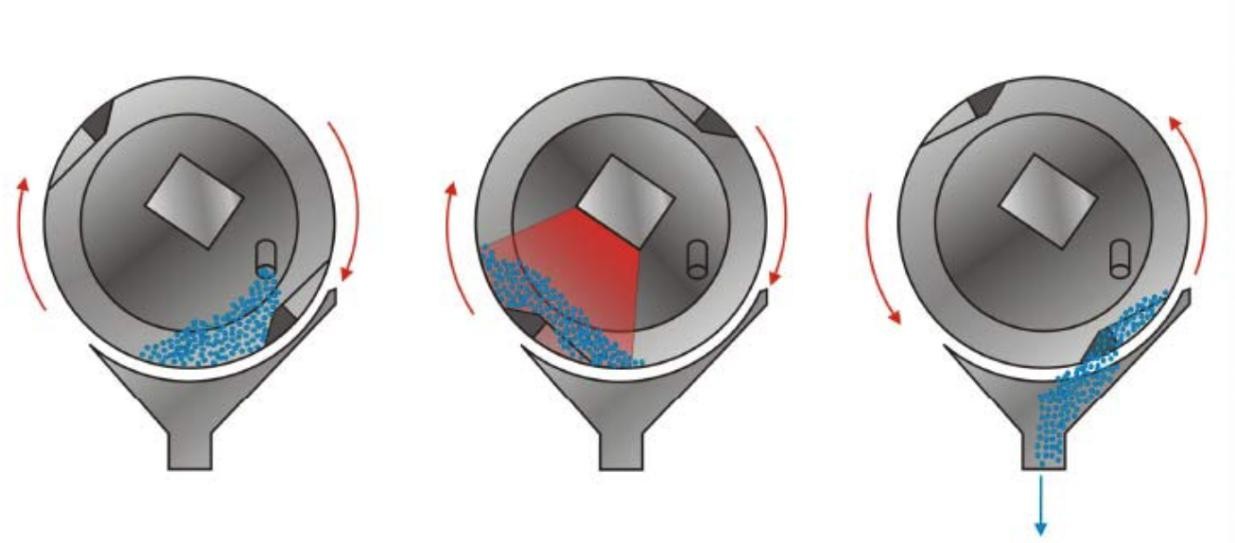

Indlela Yokusebenza

>> Kwinqanaba lokuqala, ekujoliswe kuko kuphela kukufudumeza imathiriyeli ukuya kubushushu obusetwe kwangaphambili.

Yamkela isantya esicothayo somgqomo ojikelezayo, izibane ze-infrared zesomisi ziya kuba kumgangatho ophezulu, emva koko iipellets ze-PET ziya kuba nokufudumeza okukhawulezayo de iqondo lobushushu linyuke liye kubushushu obusetwe kwangaphambili.

>> Ukomisa kunye nenyathelo lokuqaqambisa

Emva kokuba izinto zifike kwiqondo lokushisa, isantya somgqomo siya kwandiswa ukuya kwisantya esiphezulu esijikelezayo ukuphepha ukudibanisa kwezinto. Ngexesha elifanayo, izibane ze-infrared ziya kwandiswa kwakhona ukugqiba ukomisa. Emva koko isantya sokujikeleza igubu siya kuthotywa kwakhona. Ngokuqhelekileyo inkqubo yokumisa iya kugqitywa emva kwe-15-20mins. (Ixesha elichanekileyo lixhomekeke kwipropati yezinto)

>> Emva kokugqiba inkqubo yokomisa, i-IR Drum iya kukhupha ngokuzenzekelayo izinto kwaye iphinde igcwalise idrum kumjikelo olandelayo.

Ukuzaliswa ngokuzenzekelayo kunye nazo zonke iiparitha ezifanelekileyo kwiirampu ezihlukeneyo zokushisa zihlanganiswe ngokupheleleyo kwi-state-of-art yolawulo lwe-Touch Screen. Nje ukuba iiparamitha kunye neeprofayili zobushushu zifunyenwe kwizinto ezithile, iisetingi zeethisisi zinokugcinwa njengeendlela zokupheka kwinkqubo yolawulo.

Inzuzo Yethu

Ukuya kuthi ga kwi-60% ngaphantsi kokusetyenziswa kwamandla kunenkqubo eqhelekileyo yokomisa

Akukho ulwahlulo lweemveliso ezinobunzima obuhlukeneyo

Ukushisa okuzimeleyo kunye nexesha lokumisa libekwe

Ukucoca ngokulula kunye nokutshintsha izinto

Ukuqalisa kwangoko kunye nokuvala ngokukhawuleza

crystallization efanayo

Akukho iipellet ezidibanisayo kunye nokuncamathela

Ngononophelo unyango lwezinto

Iifoto zoomatshini

Ukusetyenziswa komatshini

| Ukufudumeza. | Iigranule zokufudumeza kunye nemathiriyeli yokugaywa kwakhona ngaphambi kokuqhubela phambili (umzekelo, i-PVC, i-PE, i-PP, ...) ukuphucula i-output kwinkqubo ye-extrusion. |

| Crystallization | I-Crystallization ye-PET (ii-Bottle flakes, granules, flakes), i-PET masterbatch, i-co-PET, i-PBT, i-PEEK, i-PLA, i-PPS, njl. |

| Ukomisa | Ukomiswa kweegranule zeplastiki, kunye nezinto ezisemhlabeni (umzekelo, i-PET, i-PBT, i-ABS / i-PC, i-HDPE, i-LCP, i-PC, i-PP, i-PVB, i-WPC, i-TPE, i-TPU) kunye nezinye izinto ezihamba ngokukhululekileyo. |

| Ukufuma okuphezulu | Iinkqubo zokomisa ngokufuma kwegalelo eliphezulu>1% |

| Iintlobo ngeentlobo | Iinkqubo zokufudumeza ukukhutshwa kwe-oligomers yokuphumla kunye namacandelo aguquguqukayo. |

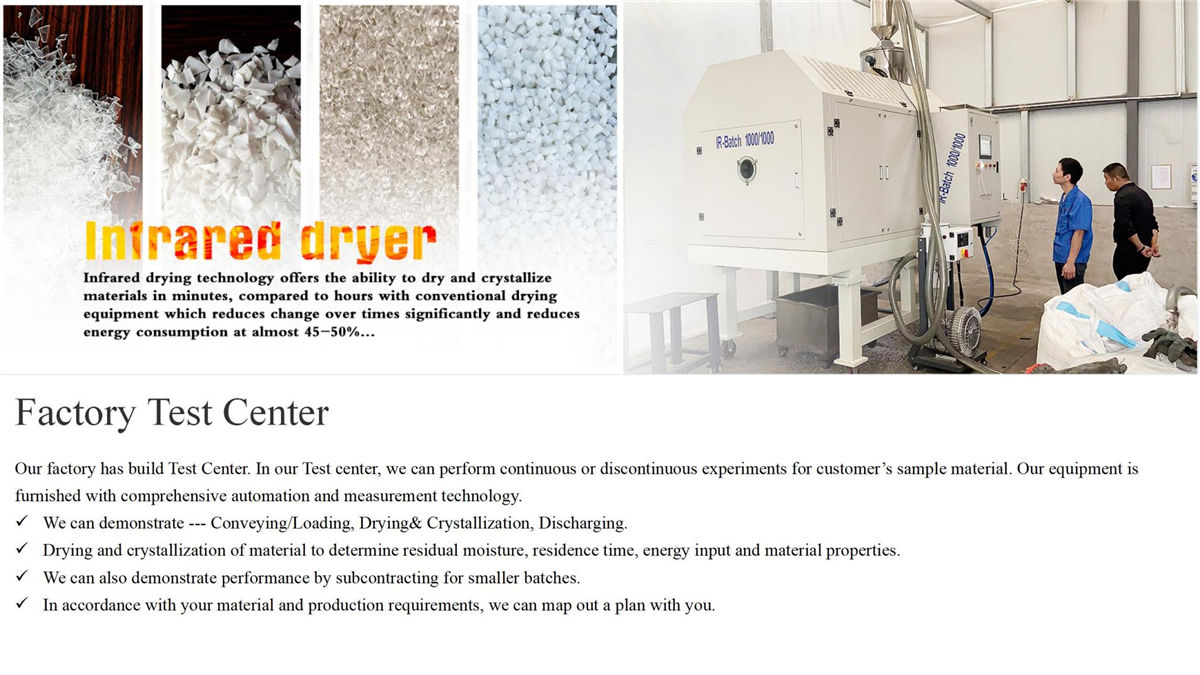

Uvavanyo lweMathiriyeli lwasimahla

Injineli enamava iya kwenza uvavanyo. Abasebenzi bakho bayamenywa ukuba bathathe inxaxheba kwiindlela zethu ezidibeneyo. Ngaloo ndlela unako zombini ukuba negalelo ngokusebenzayo kunye nethuba lokubona iimveliso zethu zisebenza.

Ukufakwa komatshini

>> Nikeza ngeNjineli enamava kumzi-mveliso wakho ukunceda ufakelo kunye novavanyo lwezinto eziphathekayo

>> Yamkela iplagi yendiza, akukho mfuneko yokudibanisa ucingo lombane ngelixa umthengi efumana umatshini kumzi-mveliso wakhe. Ukwenza lula inyathelo lofakelo

>> Nikeza ividiyo yokusebenza yofakelo kunye nesikhokelo esisebenzayo

>> Inkxaso kwinkonzo yomgca