PLA Crystallizer dryer

Isampulu yosetyenziso

| Impahla engekasilwa | I-PLA Yenziwe nguXinjiang Lanshan Tunhe |  |

| Ukusebenzisa uMtshini | LDHW-600*1000 |  |

| Ukufuma kokuqala | 9730ppm (Ngokongeza amanzi kwi-PLA Raw material ukujonga ukuba isisomisi sisebenza kakuhle kangakanani) Ivavanywe nguGerman Sartorius isixhobo sovavanyo lokufuma |  |

| Ukomisa Ubushushu iseti | 200℃ | |

| Ixesha lokumisa libekiwe | 20mins | |

| Ukufuma kokugqibela | 20ppm Ivavanywe nguGerman Sartorius isixhobo sovavanyo lokufuma |  |

| Imveliso yokugqibela | I-PET Resin eyomileyo akukho clumping, akukho pellets ezincamathelayo |  |

Indlela Yokusebenza

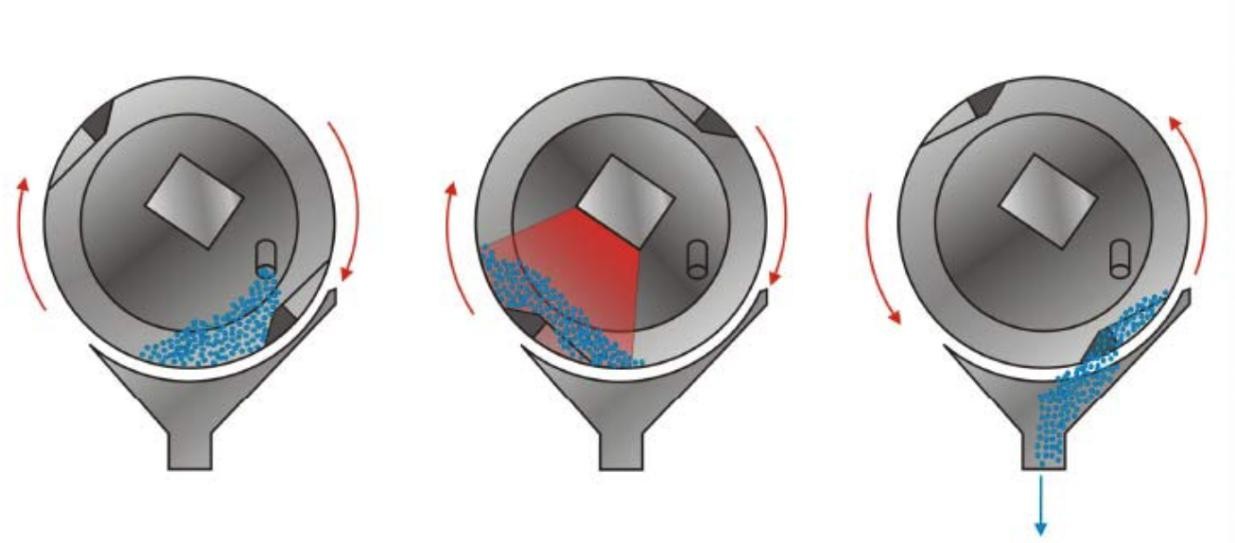

>> Kwinqanaba lokuqala, ekujoliswe kuko kuphela kukufudumeza imathiriyeli ukuya kubushushu obusetwe kwangaphambili.

Yamkela isantya esicothayo somgqomo ojikelezayo, izibane ze-infrared zesomisi ziya kuba kumgangatho ophezulu, emva koko iipellets ze-PET ziya kuba nokufudumeza okukhawulezayo de iqondo lobushushu linyuke liye kubushushu obusetwe kwangaphambili.

>> Ukomisa inyathelo

Emva kokuba izinto zifike kwiqondo lokushisa, isantya somgqomo siya kwandiswa ukuya kwisantya esiphezulu esijikelezayo ukuphepha ukudibanisa kwezinto. Ngexesha elifanayo, izibane ze-infrared ziya kwandiswa kwakhona ukugqiba ukomisa. Emva koko isantya sokujikeleza igubu siya kuthotywa kwakhona. Ngokuqhelekileyo inkqubo yokumisa iya kugqitywa emva kwe-15-20mins. (Ixesha elichanekileyo lixhomekeke kwipropati yezinto)

>> Emva kokugqiba inkqubo yokomisa, i-IR Drum iya kukhupha ngokuzenzekelayo izinto kwaye iphinde igcwalise idrum kumjikelo olandelayo.

Ukuzaliswa ngokuzenzekelayo kunye nazo zonke iiparitha ezifanelekileyo kwiirampu ezihlukeneyo zokushisa zihlanganiswe ngokupheleleyo kwi-state-of-art yolawulo lwe-Touch Screen. Nje ukuba iiparamitha kunye neeprofayili zobushushu zifunyenwe kwizinto ezithile, iisetingi zeethisisi zinokugcinwa njengeendlela zokupheka kwinkqubo yolawulo.

Inzuzo Yethu

| 1 | Ukusetyenziswa kwamandla aphantsi | Ukusetyenziswa kwamandla aphantsi kakhulu xa kuthelekiswa neenkqubo eziqhelekileyo, ngokuziswa ngokuthe ngqo kwamandla e-infrared kwimveliso. Yonga malunga ne-40% yokusetyenziswa kwamandla xa kuthelekiswa nekristali eqhelekileyo kunye nesomisi |

| 2 | Imizuzu endaweni yeeyure | Imveliso ihlala imizuzu embalwa kuphela kwinkqubo yokomisa kwaye iyafumaneka kumanyathelo angaphezulu okuvelisa.

|

| 3 | Kulula ukucoca | Igubu linokuvulwa ngokupheleleyo, akukho mabala afihliweyo kwaye linokucocwa ngokulula ngesicoci sevacuum |

| 4 | Akukho clumping | Inkqubo yokomisa i-Rotary, isantya sayo esijikelezayo sinokunyuswa ngokusemandleni ukufumana ukuxuba okugqwesileyo kweepellets. Ilungile ekuphazamisekeni, izinto eziphathekayo aziyi kuxutywa |

| 5 | Ubushushu bubekwe ngokuzimeleyo | Igubu lahlulwe laba ziindawo ezintathu zokufudumeza ezixhotyiswe nge-infrared PID sensors zinokusetwa ukomisa okanye ubushushu obukhazimlisiweyo ngokuzimeleyo.

|

| 6 | I-Siemens PLC yokulawula isikrini sesikrini | Isomisi esijikelezayo esine-infrared siyilwe ngomlinganiselo wobushushu obuntsonkothileyo. Izinto eziphathekayo kunye nokukhupha ukushisa komoya kujongwa ngokuqhubekayo ngababonisi. Ukuba kukho nakuphi na ukutenxa, inkqubo ye-PLC iya kulungelelanisa ngokuzenzekelayo |

| Iiresiphi kunye neeparamitha zenkqubo zinokugcinwa kwinkqubo yokulawula ukuqinisekisa iziphumo ezilungileyo nezinokuphinda zenziwe kwakhona. | ||

| Kulula ukusebenza |

Iifoto zoomatshini

Ukusetyenziswa komatshini

| Ukufudumeza. | Iigranuli zokufudumeza kunye nokugaya kwakhona imathiriyeli ngaphambi kokuqhubekela phambili (umzekelo, iPVC, iPE, iPP,…) ukuphucula ugqithiso kwinkqubo ye-extrusion.

|

| Crystallization | I-Crystallization ye-PET (ii-Bottle flakes, granules, flakes), i-PET masterbatch, i-co-PET, i-PBT, i-PEEK, i-PLA, i-PPS, njl. |

| Ukomisa | Ukomiswa kweegranule zeplastiki, kunye nezinto ezisemhlabeni (umzekelo, i-PET, i-PBT, i-ABS / i-PC, i-HDPE, i-LCP, i-PC, i-PP, i-PVB, i-WPC, i-TPE, i-TPU) kunye nezinye izinto ezihamba ngokukhululekileyo. |

| Ukufuma okuphezulu | Iinkqubo zokomisa ngokufuma kwegalelo eliphezulu>1% |

| Iintlobo ngeentlobo | Iinkqubo zokufudumeza ukukhutshwa kwe-oligomers yokuphumla kunye namacandelo aguquguqukayo. |

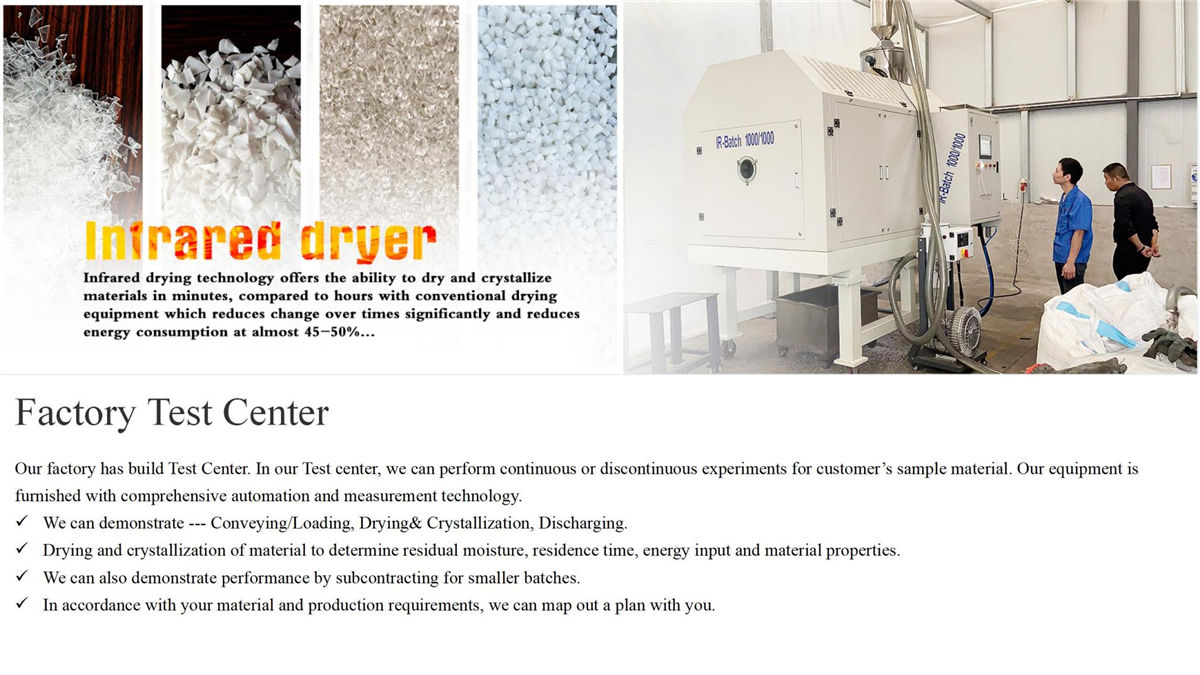

Uvavanyo lweMathiriyeli lwasimahla

Injineli enamava iya kwenza uvavanyo. Abasebenzi bakho bayamenywa ukuba bathathe inxaxheba kwiindlela zethu ezidibeneyo. Ngaloo ndlela unako zombini ukuba negalelo ngokusebenzayo kunye nethuba lokubona iimveliso zethu zisebenza.

Ukufakwa komatshini

>> Nikeza ngeNjineli enamava kumzi-mveliso wakho ukunceda ufakelo kunye novavanyo lwezinto eziphathekayo

>> Yamkela iplagi yendiza, akukho mfuneko yokudibanisa ucingo lombane ngelixa umthengi efumana umatshini kumzi-mveliso wakhe. Ukwenza lula inyathelo lofakelo

>> Nikeza ividiyo yokusebenza yofakelo kunye nesikhokelo esisebenzayo

>> Inkxaso kwinkonzo yomgca